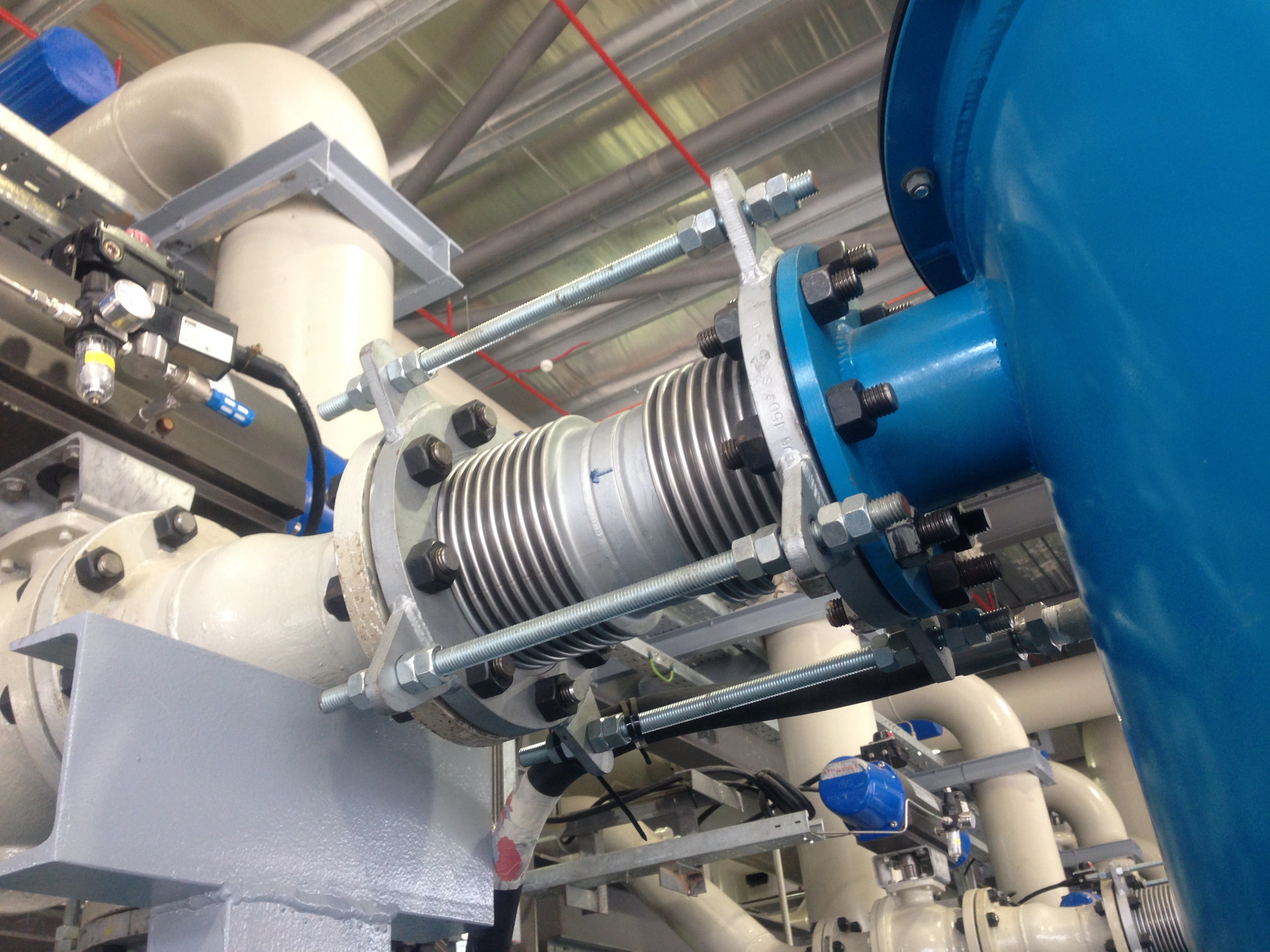

Description

EZ-Flex Metallic Expansion Joints Bellows are designed in accordance with the EJMA (Expansion Joint Manufacturer Association), ASME B31.3, ASME Sec VIII, EN standards and the experience of the engineer to ensure the proper geometry is selected. The bellows is manufactured by forming corrugations, or convolutions, in thin-walled metal cylinders. These cylinders can be inserted inside each other to form multi-ply bellows. The drawing process does not thin the bellows tube. All bellows are formed in their cold state and optional heat treatment can be performed afterward.

The ability of metallic bellows to absorb movements and cycle properly is determined by the bellows geometry and material which include total number of convolutions, convolution height, convolution pitch and radius, thickness of material and number of plies.

Bellows are designed to absorb axial, lateral and angular movement. Applying torsional movement on bellows should be avoided.

If torsional movement is present, appropriate hinge or gimbal hardware is highly recommended to counter the torque.