Description

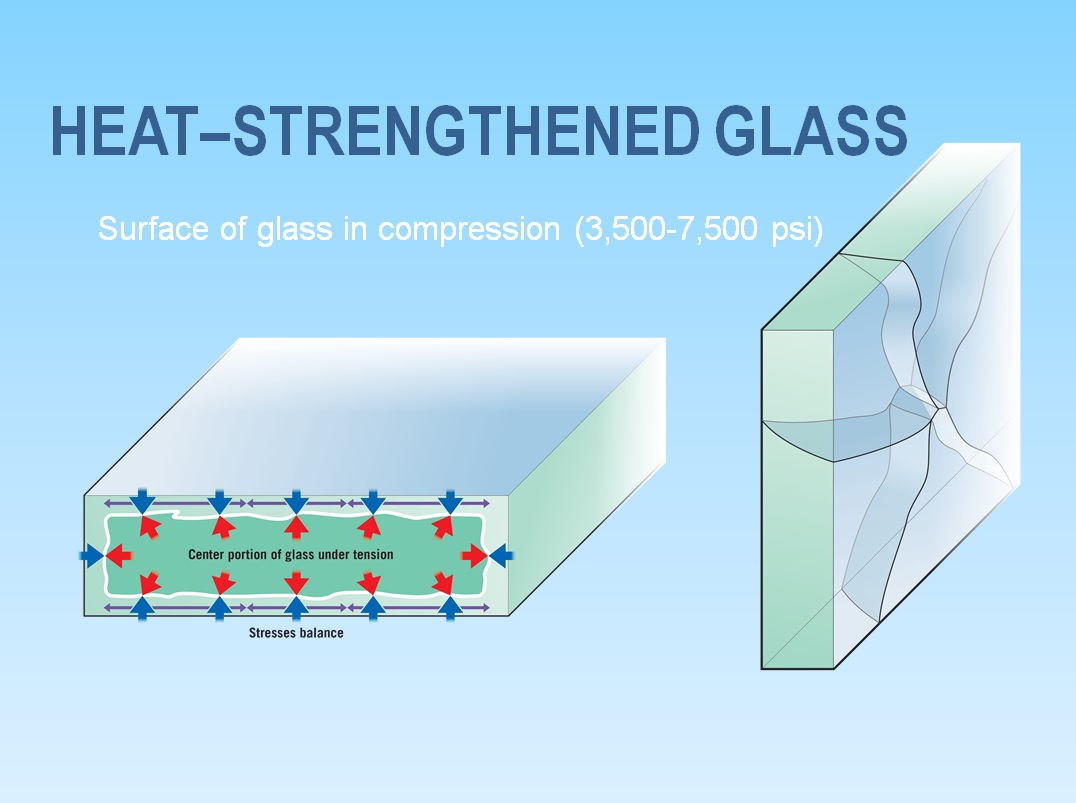

Heat-Strengthened Glass, which is widely used in the construction industry, differs from tempered glass by its properties and its manufacturing process. Heat-Strengthened Glass has a breaking resistance of approximately twice as high as annealed glass. It breaks into large pieces and does not crumble into small fragments like tempered glass. It allows the glass to remain in the window frame as the weight of the broken glass on its neighbouring pieces support each other in the frame. Therefore, it is often used in facades.

When producing heat strengthened laminated glass as compared to tempered laminated glass, heatstrengthened glass allows the interlayer of laminated glass to adhere more evenly because of a flatter finish surface and results in the facade having less optical distortion. In addi’I’ion to all the benefits mentioned, the probability of nickel sulphide induced spontaneous breakage is practically non-existent in heat-strengthened glass.

In heat-strengthened and fully tempered glass, a strain pattern, which is not normally visible, may become visible under certain light conditions. It is characteristic of these kinds of glasses and should not be mistaken as discoloration or non-uniform tint or colour and is thus not a defect.